Researchers from the Department of Energy’s SLAC National Accelerator Laboratory and Stanford University have highlighted a catalyst that can generate hydrogen in a commercial device at a lower price.

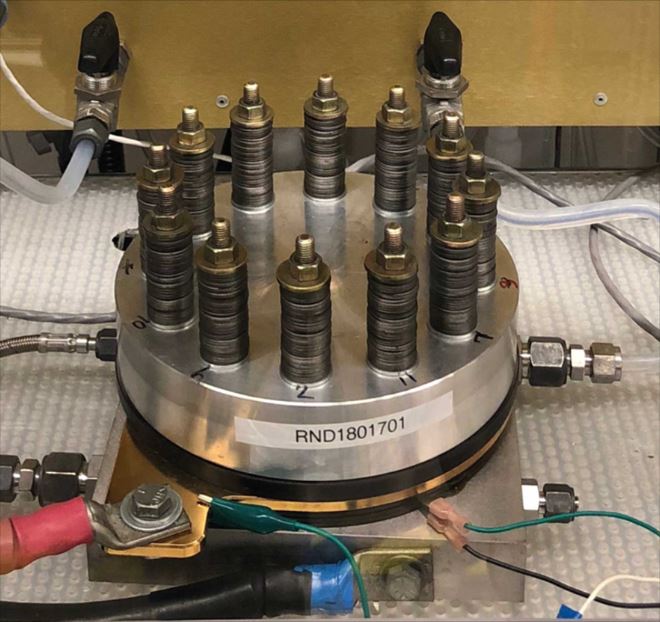

The catalyst can split water and generate hydrogen for hours in the harsh environment of a commercial device. The electrolyzer technology is based on a polymer electrolyte membrane (PEM) and has the potential for large-scale hydrogen production powered by renewable energy.

The technology has previously been held back due to the high cost of metal catalysts required to boost the chemical reactions.

The new device was manufactured by a PEM electrolysis research site and factory in Connecticut for Nel Hydrogen.

The electrolysis process uses electrical current to split water into hydrogen and oxygen. The reactions that generate hydrogen in oxygen gas take place on different electrodes using different precious metal catalysts.

In this case, Nel Hydrogen replaced the platinum catalyst on the hydrogen-generating side with a catalyst consisting of cobalt phosphide nanoparticles deposited on carbon to form a fine black power, which was produced by researchers at SLAC and Stanford.

Katherine Ayers, Vice-President for Research and Development at Nel and Co-Author of the paper, said, “The performance of the cobalt phosphide catalyst needs to get a little bit better, and its synthesis would need to be scaled up.”

“But I was quite surprised at how stable these materials were. Even though their efficiency in generating hydrogen was lower than platinum’s, it was constant. A lot of things would degrade in that environment.”