Industrial Hydrogen Generator

C10 / C20 / C30

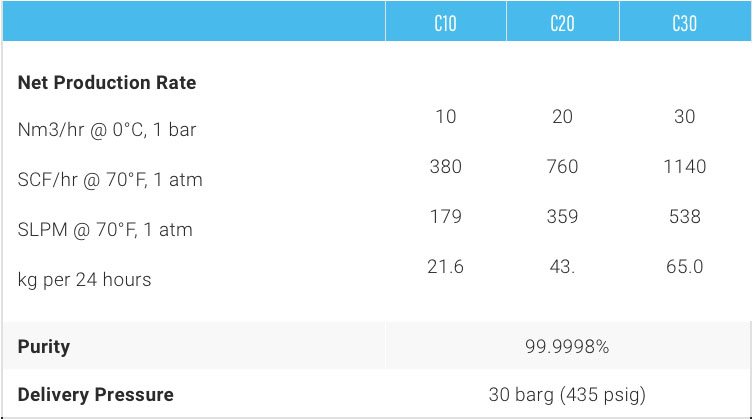

The Hydrogen C Series generators use the advanced PEM (proton exchange membrane) technology to deliver ultra pure and highly consistent supply of hydrogen gas onsite. These generators are feature packed and compact designed to ensure that it consumes less floor space.

These generators are made smarter with sensing technology. They have the capability to sense the demand for hydrogen and adjust the production quantity based on the demand. The C Series generators replace the need for liquid supply or tube trailers. They offer steady and noiseless operation.

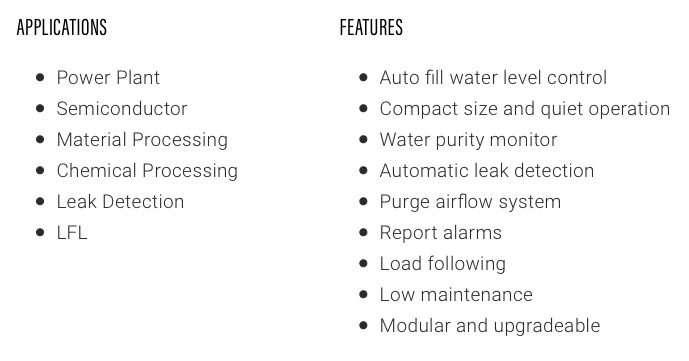

The C series generators are used in power plants, semiconductor, material processing, chemical processing, LFL and leak detection.

Main Features:

- Compact size

- Noiseless operation

- Auto-fill water level controls

- Water purity check

- Purge air flow system

- Automatic leak detection

- Load following

- Report alarms

- Low maintenance

- Modular and upgradeable

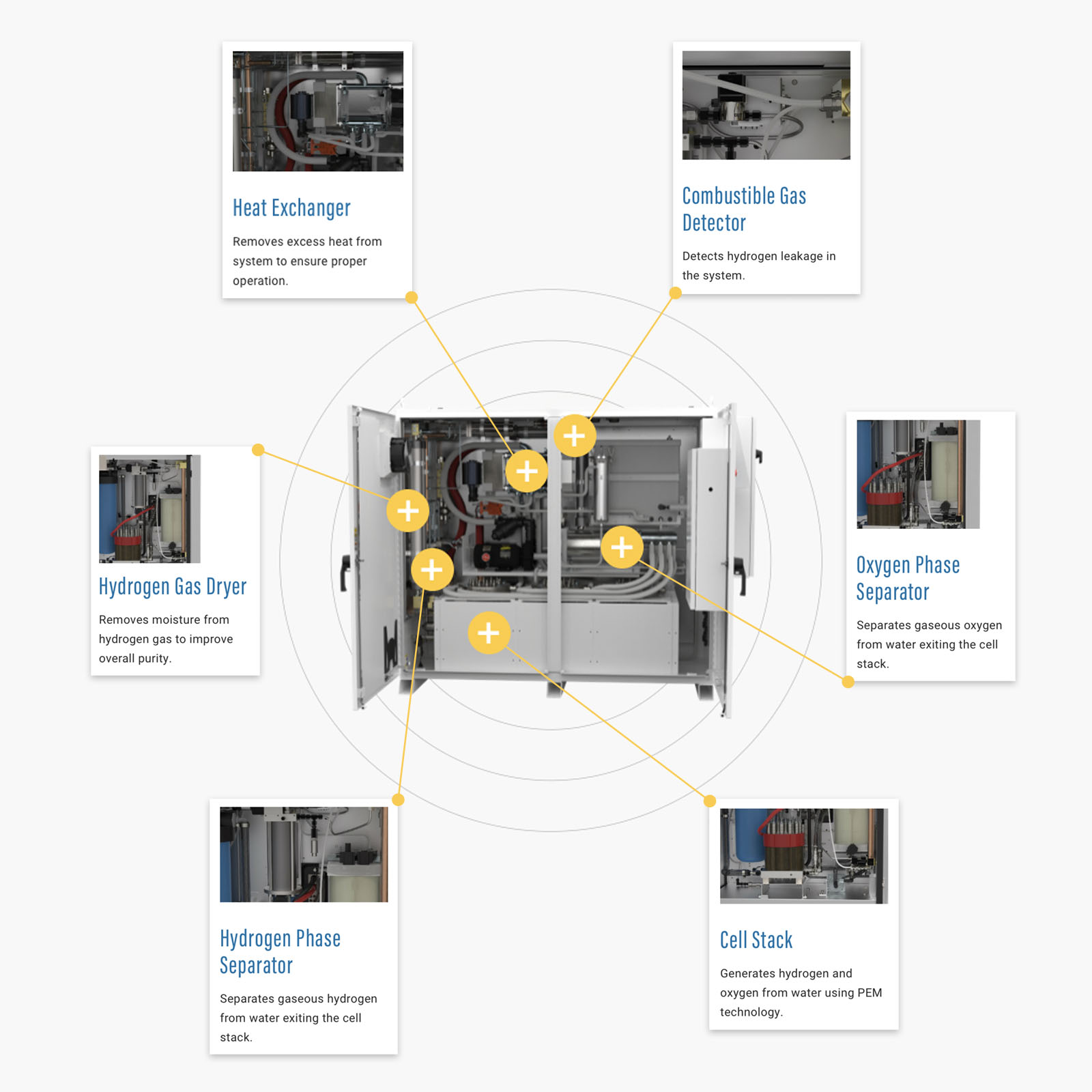

Key Components:

- Cell Stack: This is the main component that splits oxygen and hydrogen with the help of PEM technology

- Heat Exchanger: It helps in removing the additional heat from system to ensure that it works smoothly

- Combustible Gas Detector: It helps in identifying any hydrogen leakage within the system

- Hydrogen Gas Dryer: It dries up the excess moisture from hydrogen to guarantee purity

- Oxygen Phase separator: It is responsible for splitting the gaseous oxygen from deionized water that is fed to the cell stack

- Hydrogen Phase Separator: It is responsible for separating hydrogen from deionized water that passes through the cell stack