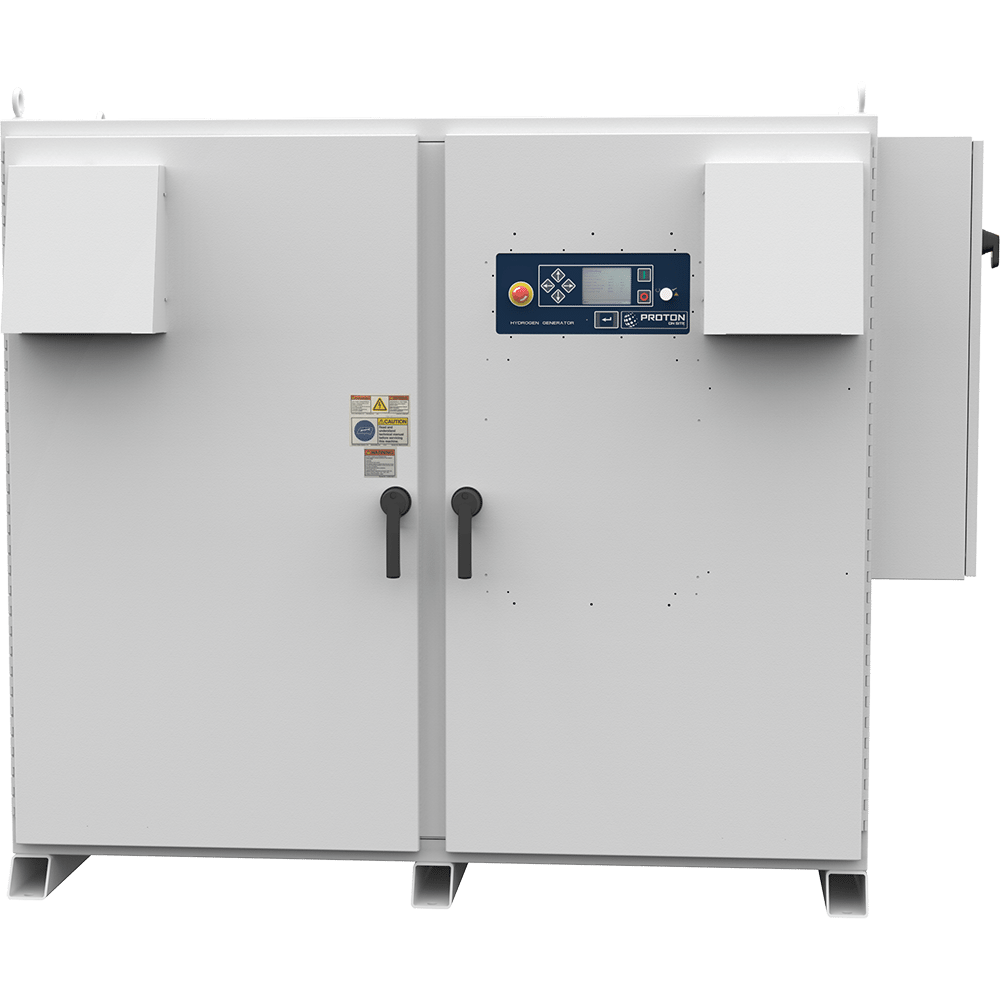

Reliable Hydrogen Generators

Hydrogen Generators for Sale

Frequently Asked Questions

Why do you need on-site gas generation?

The on-site generation comes across as a reliable method to produce nitrogen, hydrogen or zero air as per demand. Contrary to the gas cylinders, the gas generators provide peace of mind, enhanced safety and customer’s convenience. These generators are capable of producing pure gas consistently on demand.

The on-site gas generators are compact devices that don’t capture too much facility space but helps in optimizing the operation. No more hassles of moving heavy high-pressure cylinders, waiting for delivery or risks of contamination while changing cylinders.

With on-site gas generation, companies get the security of uninterrupted supply available in an easy to use plug-and-play package.

What makes on-site gas generators green/ sustainable?

When compared to other gas generators using hydrogen-generating electrolysis technology, NEL Hydrogen generators use no KOH to operate. As a result, there are no carbon dioxide byproducts formed in the hydrogen production process. They use PEM (proton exchange membrane) electrolysis to disintegrate deionized water and split it into hydrogen and oxygen.

How does PEM Electrolysis split water?

PEM (proton exchange membrane) water electrolysis is a safe and effective way to disintegrate pure deionized water (H2O) and split it into two constituent parts – hydrogen (H2) and oxygen (O2) following an electrochemical reaction. When a DC voltage is passed through an electrolyzer, deionized water (H2O) fed to the anode or oxygen, electrode is oxidized to form oxygen and protons, and the electrons are released. The protons or H+ ions are passed through the PEM to the hydrogen electrode or cathode where they come in contact with electrons released from the other side of the circuit and form hydrogen gas.